The Single Strategy To Use For Laser Cutting Systems

The Single Strategy To Use For Laser Cutting Systems

Blog Article

When it comes to present day manufacturing, the precision and performance of laser cutting technological innovation are definitely recreation-altering. Laser reducing machines have revolutionized industries by giving a means of slicing resources with unparalleled precision. In the event you’ve at any time marveled in the intricate styles on steel or questioned how elaborate styles are generated so seamlessly, it’s normally the function of the industrial laser reducing machine.

Enable’s get started with the basic principles: a laser cutter is actually a Instrument that uses a laser beam to chop supplies. This beam is extremely concentrated and generates superior temperatures to soften or vaporize the fabric, producing precise cuts. In contrast to conventional strategies, which might use mechanical blades, a laser cutter offers a degree of precision that is nearly unmatched. Picture wanting to carve a fragile pattern using a hammer—Plainly, a laser cutter is a great deal extra refined!

Industrial laser cutting normally takes this know-how to the next stage, delivering methods for giant-scale operations. These machines are built to take care of hefty supplies and significant creation volumes, making sure that even essentially the most demanding projects are accomplished with high performance. Imagine it because the distinction between employing a precision knife for sensitive paper crafts and a powerful noticed for chopping through thick Wooden.

A Biased View of Laser Cutting Systems

On this planet of CNC laser cutting, the “CNC” means Laptop or computer Numerical Command. This technological know-how permits automated and really precise cuts by subsequent digital layouts. In the event you’ve at any time applied a pc to draw and then seen that drawing come to daily life, CNC laser slicing is effective in the same way, translating digital models into Actual physical cuts. It’s like having a virtual designer with the precision of a laser.

On this planet of CNC laser cutting, the “CNC” means Laptop or computer Numerical Command. This technological know-how permits automated and really precise cuts by subsequent digital layouts. In the event you’ve at any time applied a pc to draw and then seen that drawing come to daily life, CNC laser slicing is effective in the same way, translating digital models into Actual physical cuts. It’s like having a virtual designer with the precision of a laser.The 7-Second Trick For Laser Cutting Technology

Precision laser cutting just isn't pretty much building cuts; it’s about generating them ideal each and every time. The laser may be altered to realize distinct depths and widths, ensuring that each Reduce is exactly exactly where it really should be. This really is important for purposes wherever even a slight deviation may lead to major problems. Think about it as a surgeon’s scalpel, wherever precision is not merely significant but Totally significant.

Precision laser cutting just isn't pretty much building cuts; it’s about generating them ideal each and every time. The laser may be altered to realize distinct depths and widths, ensuring that each Reduce is exactly exactly where it really should be. This really is important for purposes wherever even a slight deviation may lead to major problems. Think about it as a surgeon’s scalpel, wherever precision is not merely significant but Totally significant.Laser reducing tools comes in different varieties, each personalized to specific requires. Whether You'll need a little desktop design for pastime initiatives or a large industrial machine for factory use, there’s a laser chopping Resolution available in your case. These devices change in electric power, pace, and capabilities, so it’s important to select the appropriate one to your specific application.

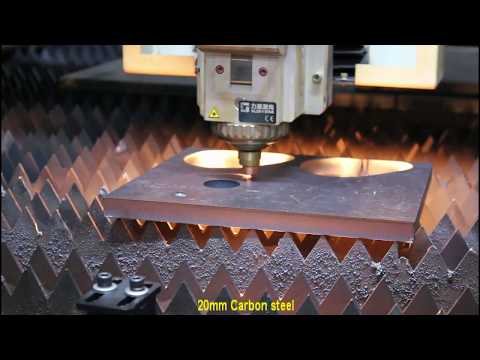

Sheet metallic laser cutters certainly are a Specific class of laser slicing machines created especially for slicing metal sheets. They are widely used in industries starting from automotive to aerospace because of their capacity to take care of steel with precision and pace. Picture a sheet of metal similar to a blank canvas, along with the laser cutter as being the artist who generates advanced and delightful patterns with unbelievable accuracy.

Laser reducing providers are Yet another important aspect of this technological know-how. Not everyone needs to speculate in their own personal laser cutting device, particularly if they only want occasional cuts or deficiency the Place for this kind of products. Quite a few companies offer laser cutting companies where you can ship your patterns and also have them Lower with higher precision. It’s like outsourcing your artwork to a talented Skilled.

Laser slicing techniques combine various factors to deliver the desired success. Within the laser supply for the reducing mattress, plus the control software, each Component of the program will work alongside one another to be certain a flawless Procedure. It’s a tad similar to a symphony orchestra, the place Every single musician has a certain job, and only by Doing the job jointly do they develop a harmonious performance.

On the subject of laser cutting technological innovation, the evolution has actually been quick and extraordinary. In the beginning utilized mainly for slicing metals, these equipment now take care of an array of products including plastics, wood, as well as fabrics. This flexibility will make laser cutting technological know-how a valuable Resource in innumerable industries. Envision getting a Swiss Army view the article knife that will take care of nearly any substance—This can be what present day laser chopping know-how presents.

The accuracy of laser reducing devices is really exceptional. They're able to Minimize resources to in microns with the intended design, guaranteeing that even quite possibly the most intricate specifics are preserved. This standard of precision is especially useful in industries wherever correct measurements are crucial. Imagine it as the difference between a tailor-made fit and off-the-rack clothes—the healthy is simply perfect every time.

Some Known Factual Statements About Laser Cutting Machine

An additional advantage of laser chopping engineering is its efficiency. Contrary to standard chopping techniques that might demand various methods or tools, laser slicing normally completes the activity in one go. This not simply hurries up production but also minimizes product squander. It’s like having a significant-speed educate that will get you to the desired destination immediately and proficiently with no unneeded stops.Inside the context of industrial apps, the robustness of laser cutting equipment is crucial. These equipment are constructed to endure the calls for of constant Procedure, generally operating 24/7 in high-volume options. Their toughness guarantees CNC Laser Cutting steady performance and dependability, which can be important for preserving manufacturing schedules. It’s like having a weighty-responsibility truck that reliably provides merchandise working day following day.

Among the outstanding elements of laser slicing is its capability to develop clear and specific edges. This decreases the necessity for article-processing, such as sanding or finishing, that may be time-consuming and dear. The result is usually a clean, completed product or service That always needs negligible additional perform. Picture ending a craft venture without glue spills or rough edges—it’s that clean!